To discuss your needs or for a quote contact us on (+61 3) 9580 8652 or send us an email:

sales@alfredlewis.com.au

Manufacturing Equipment and Capabilities

CNC MILLING

Alfred Lewis Engineering has a broad spread of CNC milling capability across its’ nine CNC milling centres. Our horizontal and vertical mills offer versatile machining possibilities:

- 10 pallet horizontal and twin pallet vertical machining for unmanned operation and increased efficiency

- Machining envelopes up to 2000mm x 1200mm x 750mm

- Rapid fixture location system to minimise change-over and set up times

- High speed 3D milling

- High pressure coolant to deliver higher metal removal rates

- In-process Renishaw probes for work piece set up and gauging

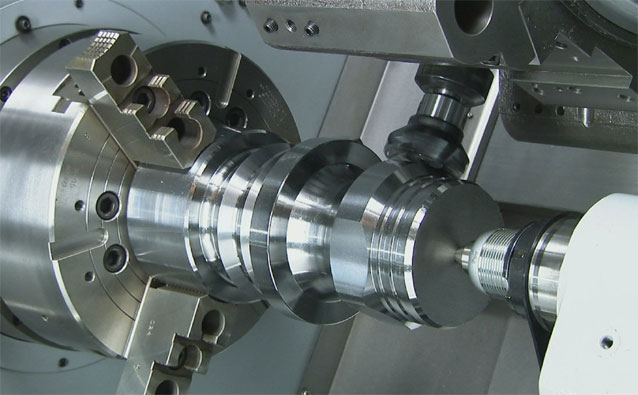

CNC TURNING

Alfred Lewis Engineering’s CNC turning capability is embodied in nine CNC turning centres with features such as:

- Multi-tasking auto bar feed for unmanned operation

- Twin spindle, twin chucks

- 5 & 7 axis

- Robot load/unload for unmanned operation

- Dual SMW steadies for turning of long shafts

- In-process Renishaw probes for work piece set up and gauging

- Maximum turning diameter of 900mm across 1600mm bed length

OTHER SERVICES

For low volume, proto-typing or one-off jobs, Alfred Lewis maintains a comprehensive manual turning and milling department with a deep hole drill.

In addition to this, we can also provide welding to AS 2885.2, fine grinding, polishing and a variety of surface treatments.

Contact us today to discuss your requirements